| View All 268358 |

|

Member's Points

Sign Up Time: 16 years,

Point: 237

|

|

| Information |

SellGranulating Equipment > Spheroid Granuled Machine > Centrifugal Spheroid Granule Machine SY-S

Centrifugal Spheroid Granule Machine

SY-SM-400 TYPE

Description

In the development of spherical granule technology, the development for tiny granule is the focus. SHANG YUH introduces Spherical granule Machine to meet the requirement. The granulation process is that before extruding operation the solid raw materials need be well mixed with the liquids. Then the mixed ingredients go through this Spherical Granule Machine to have its Spherical Granule. The dispersing ability, flow ability, moisture content stability, granule durability and outlook appearance of spherical granules become excellent after this process.

-

Features

-

Centrifugal force is the processing force. The mixed ingredients are spun at high speed in a grooved disk by centrifugal force. With the spinning force to push the ingredients to contact grooved disk, the mixed ingredients are shaped into spherical granule.

Because of high spinning force and grooved disk, the granules are formed to same size and shape. The granule yield rate is over 90%, the rework is less that results in clean working place and low production cost. As for heat sensible ingredients there is a cooling jacked to protect ingredient from overheating. Continuous production could be designed based on client' request.

-

Specification

-

|

Model |

SY-SM-230 |

SY-SM-400 |

SY-SM-700 VH/VL |

SY-SM-1000 VH/VL |

|

OPERATION VOLUME/FULL VOLME |

1L / 5L |

4L / 18L |

20L / 90L |

60L / 275L |

|

DIMENSION (LXWXH) |

110X540X1000 |

1300X700X1200 |

2200X1100X1400 |

2400X1400X1500 |

|

REVOLUTION (r.p.m) |

280~1120 r.p.m |

250~1000 r.p.m |

VH50HZ 150~600r.p.m |

VH50HZ 52~208r.p.m |

|

340~1350 r.p.m |

300~1200 r.p.m |

60HZ 180~720r.p.m |

60HZ 60~250r.p.m |

|

DRIVE MOTOR |

1HPX4P |

3HPX4P |

5HPX4P |

7.5HPX4P |

|

TOTAL WEIGHT (APP.) |

approx. 430kg |

approx. 710kg |

approx. 1,300kg |

approx. 1,650kg |

|

-

Usaga

-

Pharmaceuticals、foods (health foods)、chemical ingredients and foods additives.

-

-

|

|

|

|

|

|

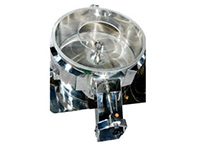

High Speed Ball Rolling Disk |

|

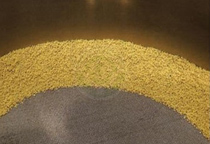

High Speed Granule and Sphere |

|

Put Products Device |

|

|

|

|

|

|

|

|

|

|

|

|

Chinese Medicines |

|

Western Medicines |

|

Health Foods |

|

|

|

|

|

|